RESIN IMPREGNATED PAPER (RIP) BUSHING

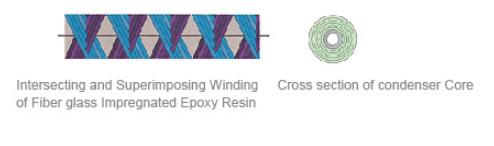

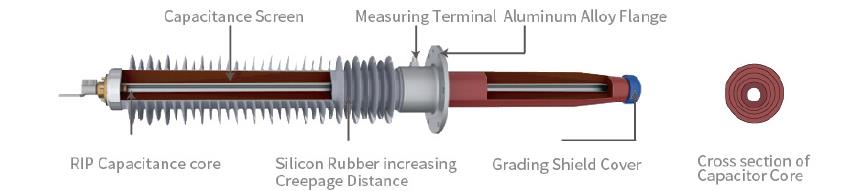

The main insulation of the RIP bushing is Resin Impregnated Paper Insulation which is wound with corrugated paper first, and aluminum foil wrapping at intervals basing on the insulation thickness required by the design to form a capacitor core with series capacitance structure. The core is cured (polymerized) after vacuum drying and epoxy resin resin impregnation. Insulating paper,highperformance epoxy resin and aluminum foil are all international imported brand products, and thematerials used are the same as those of ABB and HSP international first-line casing manufacturers. Thestability and reliability of materials have been verified and evaluated by the market for more than 30 years.

Service and Maintenance

High seismic resistance: it can resist earthquakes of intensity 9 levels and above

High seismic resistance: it can resist earthquakes of intensity 9 levels and above

Minimum workload of technical maintenance simple installation

Minimum workload of technical maintenance simple installation

Easy installation

Easy installation

lt can also be used at extremely low temperature (-60C)

lt can also be used at extremely low temperature (-60C)

All bushings are subject to the specified service temperature standard :-50 to +55'C

All bushings are subject to the specified service temperature standard :-50 to +55'C

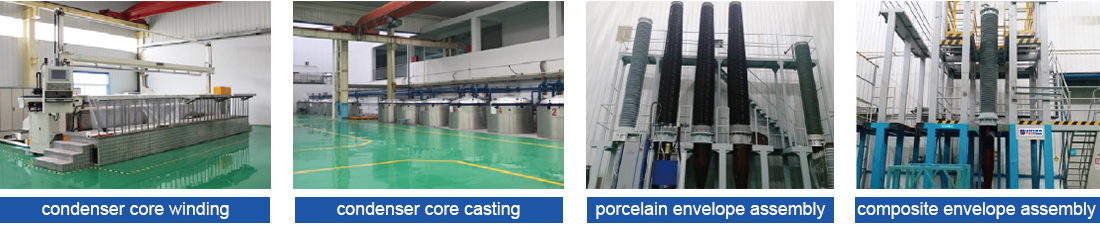

According to the customer' S demand, the external insulation of bushing can be porcelain or silicone rubber

According to the customer' S demand, the external insulation of bushing can be porcelain or silicone rubber

Silicone rubber external insulation products are completely dry structure, lighter weight, High hydrophobic, good anti-pollution performance and better explosion-proof performance

Silicone rubber external insulation products are completely dry structure, lighter weight, High hydrophobic, good anti-pollution performance and better explosion-proof performance

There is no risk of fire due to oil leakage

There is no risk of fire due to oil leakage

Structure

No down porcelain shell, light weight, small size

No down porcelain shell, light weight, small size

It can be used with different external insulation

It can be used with different external insulation

Ensure safe use in severely polluted (harsh) environment

Ensure safe use in severely polluted (harsh) environment

it's easy to installation from any different angles

it's easy to installation from any different angles

On line monitoring

The bushing can be equipped with on-line monitoring system according to the user's needs, including insulation status display device, bushing dielectric loss measurement device, real-time partial discharge monitoring device for bushing operation, so as to fully meet the customer's needs. Ensure long-term operation safety and reliability.

Structure features

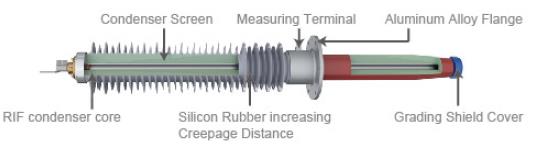

RESIN IMPREGNATED FIBER (RIF) BUSHING

The product not only meets the requirements of GB /T 4109-2008 and IEC60137-Ed.7.0 but also has the following significant advantages

The main insulation of this product adopts pure solid condenser core, without special maintenance;

The main insulation of this product adopts pure solid condenser core, without special maintenance;

The insulation design of the bushing has a large insulation margin, and the semiconductor material is used as the capacitor screen, which greatly improves the initial voltage of the bushing partial discharge;

The insulation design of the bushing has a large insulation margin, and the semiconductor material is used as the capacitor screen, which greatly improves the initial voltage of the bushing partial discharge;

Flame retardant insulation material, no decomposition, stable electrical performance, extremely low risk of combustion and explosion;

Flame retardant insulation material, no decomposition, stable electrical performance, extremely low risk of combustion and explosion;

Compact structure, small size, lightweight, easy to transport and install;

Compact structure, small size, lightweight, easy to transport and install;

Glass fiber reinforced winding and optimized mechanical ply design has high bending strength and excellent mechanical properties;

Glass fiber reinforced winding and optimized mechanical ply design has high bending strength and excellent mechanical properties;

Excellent high and low-temperature resistance, maximum temperature resistance + 135 ℃ (electrostatic precipitator), minimum temperature resistance – 196 ℃ (liquid nitrogen environment);

Excellent high and low-temperature resistance, maximum temperature resistance + 135 ℃ (electrostatic precipitator), minimum temperature resistance – 196 ℃ (liquid nitrogen environment);

The results show that the silicone rubber composite envelope has excellent antifouling and anti-seismic performance, and can be used in heavily polluted areas and earthquake areas;

The results show that the silicone rubber composite envelope has excellent antifouling and anti-seismic performance, and can be used in heavily polluted areas and earthquake areas;

Long service life, low cost of long-term operation;

Long service life, low cost of long-term operation;

The product can be designed according to the special requirements of users;

The product can be designed according to the special requirements of users;

Products can also provide high-strength porcelain climbing skirts for users to choose;

Products can also provide high-strength porcelain climbing skirts for users to choose;

It can meet the requirements of the smart grid. The bushing can be equipped with an intelligent online monitoring device developed by our company, which can realize on-line monitoring of the insulation state of bushing;

It can meet the requirements of the smart grid. The bushing can be equipped with an intelligent online monitoring device developed by our company, which can realize on-line monitoring of the insulation state of bushing;

Structure features